What to Know About Well Tank Pressure for Optimal Performance?

Understanding well tank pressure is crucial for optimal performance in water systems. John Smith, a renowned expert in water well systems, emphasizes, "Proper pressure management can prevent costly repairs." His insights remind us that well tank pressure greatly affects system efficiency.

Maintaining the right pressure is not always straightforward. Many homeowners overlook this vital aspect. Insufficient pressure can result in inadequate water flow. Excessive pressure can damage pipes and equipment. It’s essential to be proactive and regularly check the pressure levels.

Many people think they can ignore their well tank pressure. However, this can lead to inefficiencies and unnecessary expenses. Armed with basic knowledge, owners can avoid common pitfalls. Regular maintenance checks are key. Understanding your well tank pressure makes a significant difference in your water supply quality.

Understanding Well Tank Pressure and Its Importance

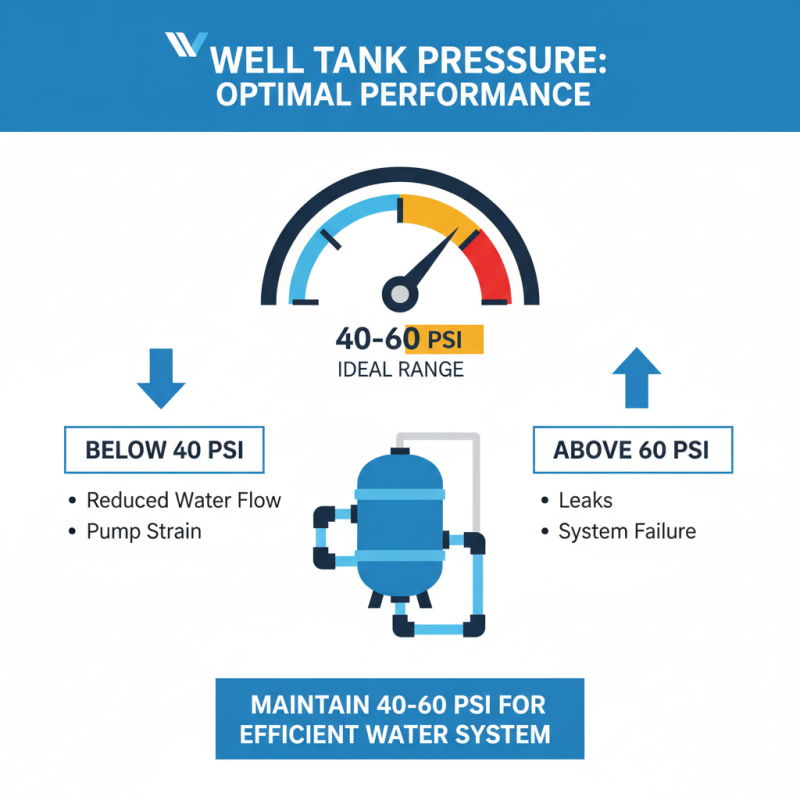

Understanding well tank pressure is crucial for efficient water system performance. Proper pressure ensures consistent water flow and prevents system damage. According to industry studies, maintaining pressure between 40 and 60 psi is ideal for most residential systems. This range balances adequate water supply with pump functionality.

A well tank functions like a balloon. When pressure is low, the pump runs constantly. This can lead to overheating and burnout. If pressure is too high, it risks damaging pipes or fixtures. A safe and efficient system often relies on regular pressure checks. Consider scheduling maintenance every six months.

**Tip:** Install a pressure gauge to monitor well tank performance. This tool helps you catch fluctuations early. Be aware of how pressure affects your water quality. High pressure can wear out plumbing quickly. Regular inspection ensures longevity and better usage. Adjustments may be necessary over time. Reassessing your system can reveal hidden problems.

Components Affecting Well Tank Pressure Levels

Well tank pressure is crucial for efficient water delivery. Various components can impact these pressure levels, including the pressure switch, air volume control, and tank bladder. Each of these parts plays a significant role. The pressure switch regulates when the pump starts and stops. If it's faulty, water pressure may fluctuate unexpectedly.

Air volume control is critical as well. A lack of air can lead to waterlogged tanks. This may cause your pump to cycle too frequently. More cycling means increased wear on the pump. Hence, keeping an eye on your air volume is essential for longevity.

**Tip:** Regularly check the air pressure in the tank. It should typically be set at 2 psi below the cut-in pressure of the switch.

The bladder inside the tank also matters. Over time, bladders can develop leaks or become stiff. This affects how well your well tank maintains pressure. You may need to replace a worn bladder to restore optimal performance.

**Tip:** Inspect your tank regularly for signs of wear. Look for rust, leaks, or any inconsistencies in pressure levels.

Well Tank Pressure Levels

This chart represents the average pressure levels in a well tank across different conditions. Understanding these pressure levels is crucial for optimal performance and maintenance of the well system.

Optimal Pressure Range for Well Tanks Explained

Maintaining the optimal pressure range in your well tank is crucial for its performance. Typically, the ideal pressure setting is between 40 and 60 psi. This range ensures efficient water flow and prevents pump strain. When the pressure dips below this range, you may notice a decrease in water availability. Conversely, excessive pressure can lead to leaks and system failures.

Regularly checking the tank's air pressure is important. Use a pressure gauge for an accurate reading. Adjustments might be necessary as seasons change. If you encounter persistent issues, reflection is key. Why is the pressure fluctuating? Could there be a leak or a faulty valve? Sometimes, it’s a simple oversight that can lead to bigger problems down the line.

A dysfunctional well tank can disrupt daily activities. If you notice odd noises from your system, it might be a warning sign. Don't ignore them. Make sure to perform routine inspections. This can save you time and money in the long run. Remember, a little maintenance goes a long way. It's easy to overlook these details, but staying vigilant ensures optimal performance.

Signs of Improper Well Tank Pressure to Watch For

Maintaining proper well tank pressure is critical for optimal system performance. Several signs indicate improper pressure in well tanks. For instance, if your water flow is erratic, it may signal that pressure levels are off. According to the Water Systems Council, about 40% of homes rely on private wells, making this issue even more pressing.

Another sign to watch for is frequent cycling of the pump. A well-functioning system should have a minimal need for the pump to turn on and off. Excessive cycling not only wastes energy but can also shorten the lifespan of your pump. Additionally, if you notice your water pressure fluctuating drastically, it’s time to check the pressure gauge.

Fluctuating water temperature can also hint at pressure issues. Cold water entering a warm tank can lead to condensation. This creates rust over time. You might also experience water hammer noises, indicating pressure problems.

Tip: Ensure air levels are balanced in your tank. Low air pressure might mean tank corrosion is imminent. If unsure, consulting a professional can prevent costly repairs.

Maintenance Tips for Maintaining Ideal Well Tank Pressure

Maintaining the ideal pressure in your well tank is essential for optimal performance. Regular checks help avoid common issues like water hammer and frequent cycling. These problems can lead to unnecessary wear on your water system. Low pressure can cause insufficient water flow, which may interrupt daily activities.

To keep the pressure right, start with regular inspections. Check the pressure gauge monthly to monitor levels. If the readings fluctuate, your tank might need adjustment. Remember to inspect the tank's bladder. A ruptured bladder can lead to complete failure. Replacing it is vital for proper function.

Think about the air charge too. A well-tank's air pressure should ideally be set at 2 psi below the cut-in pressure of your pump. It’s not just about water levels; air plays a critical role. Don't wait for signs of trouble. Proactive measures save time and money. Reflect on your current practices and make necessary changes to ensure reliability.

Related Posts

-

2025 Guide: How to Choose the Best Water Cleaning System for Your Home

-

2025 How to Build an Effective Filter System for Your Needs

-

Understanding the Importance of a Well Water Filter System for Your Family's Health

-

Why You Need Water Filters for Well Water Safety?

-

Best Well Water Filter Systems for Clean and Safe Drinking Water

-

10 Essential Tips for Choosing the Best Water Filtration System for Your Home